Flat and low-slope roofs in Seattle have a tougher job than most. Constant rain, limited drying time, and long stretches of damp weather mean roofing systems here need to manage moisture day after day—not just survive the occasional storm.

PVC roofing has become a popular option across Seattle for exactly that reason. You’ll see it on commercial buildings, townhomes with rooftop decks, and low-slope residential roofs where traditional materials struggle with standing water and long-term exposure.

But while PVC performs well in this climate, it isn’t a one-size-fits-all solution.

This page breaks down what PVC roofing is, how it performs in Seattle’s conditions, what affects cost and lifespan, and how it compares to other flat roofing systems.

The goal isn’t to push a single answer—it’s to give you clear, practical information so you can decide whether PVC makes sense for your roof, your building, and your long-term plans.

Key Takeaways

- PVC roofing performs well on Seattle’s flat and low-slope roofs, where rain, moisture, and limited drying time are constant.

- Heat-welded seams create a continuous waterproof barrier, helping reduce leaks and ponding issues.

- Resists mold, algae, and moisture, keeping maintenance lower than many flat roofing systems.

- Handles cool, wet weather and thermal movement, reducing cracking and seam stress over time.

- Costs more upfront than basic options, but offers strong long-term value when properly installed.

- Most effective on commercial and modern residential low-slope roofs.

- Best results come from experienced, certified PVC installers.

What is PVC Roofing?

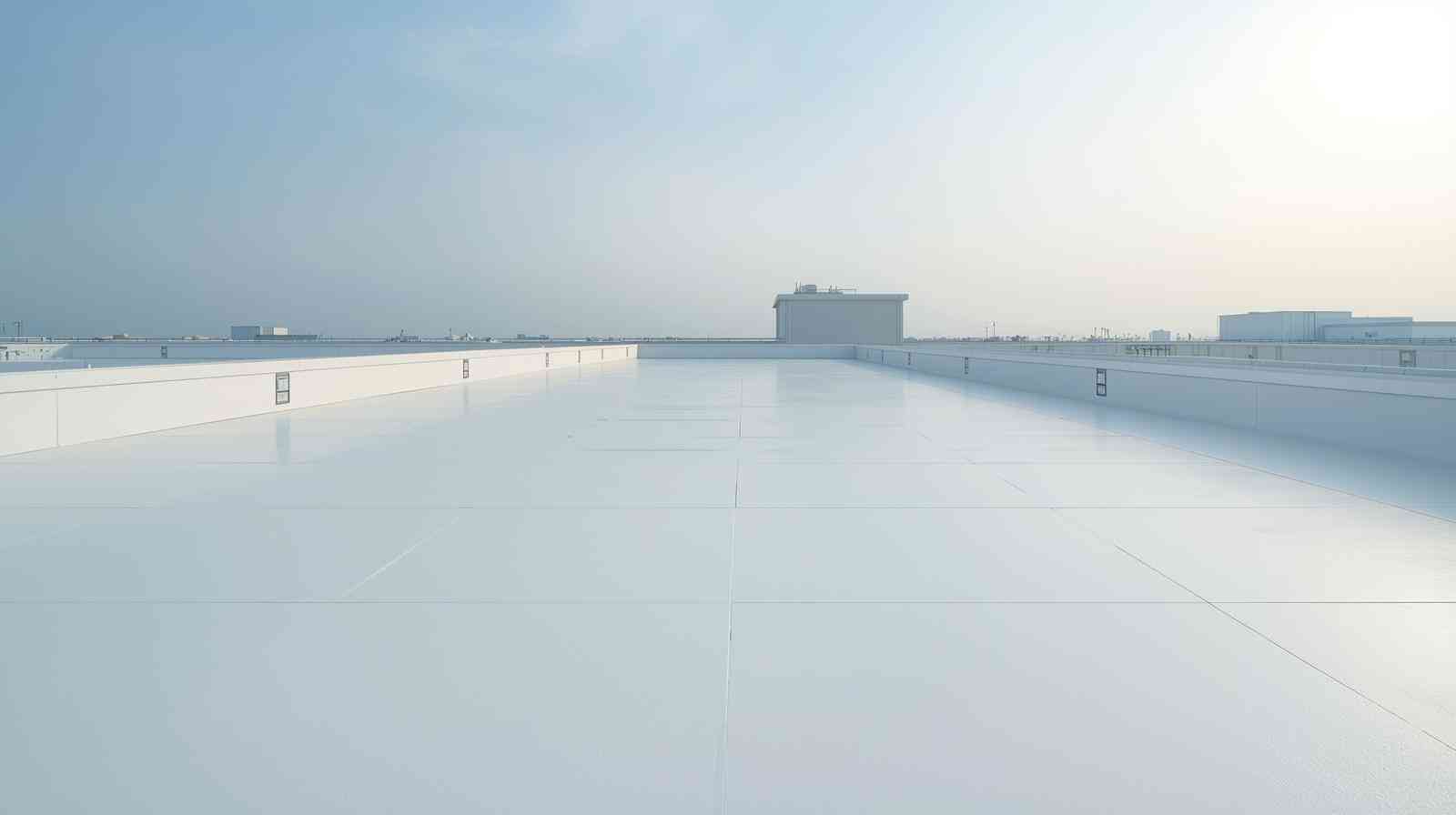

PVC roofing is a single-ply membrane roofing system made from polyvinyl chloride, commonly used on flat and low-slope roofs across Seattle.

Unlike overlapping systems such as shingles, PVC roofing is installed in large sheets that are heat-welded at the seams, creating a continuous, watertight surface.

This seamless design is especially effective in Seattle’s climate, where roofs are exposed to persistent rainfall, standing moisture, and limited drying time.

PVC functions as a protective membrane over the roof deck, helping manage water intrusion while maintaining flexibility under temperature changes.

Because of this balance between durability and moisture resistance, PVC roofing is widely used on commercial buildings, multi-family properties, and certain residential low-slope roof designs.

Developed for commercial use decades ago, modern PVC roofing systems benefit from long-term material refinements that improve performance, strength, and weather resistance.

When properly installed and maintained, PVC roofing can provide decades of reliable service, making it a practical option for property owners seeking a long-term low-slope roofing solution in Seattle.

Why PVC Roofing Performs Well in Seattle’s Climate

PVC roofing aligns closely with what Seattle’s climate demands from a low-slope roofing system: dependable waterproofing, stable seams, and materials that tolerate constant moisture, moderate temperature changes, and seasonal wind exposure.

When properly installed, PVC forms a continuous membrane that performs reliably through prolonged rain cycles and extended periods of cloud cover.

For flat and low-slope roof owners, this typically results in fewer leak-related issues, reduced weather-driven disruptions, and consistent long-term performance when the system is maintained as recommended.

Because Seattle roofs are exposed to moisture more often than they are fully dry, roofing systems here must prioritize water management and material stability over appearance alone.

PVC roofing is well-suited to these conditions, which is why it remains a common choice for low-slope applications throughout the region.

Resistance to Persistent Rain and Moisture

Seattle’s long wet seasons place ongoing stress on flat and low-slope roofs, particularly during months when rainfall is frequent and drying time is limited.

PVC roofing systems are designed to handle prolonged moisture exposure without absorbing water or degrading under damp conditions.

The membrane’s construction and seam integrity help limit common moisture-related failures that occur during repeated storm cycles.

This makes PVC a practical option for properties where roofs remain shaded, surrounded by trees, or exposed to consistent rainfall for much of the year.

As a result, PVC roofing often delivers stable moisture performance across a wide range of building types in Seattle, from commercial facilities to modern residential low-slope designs.

Mold, Algae, and Chemical Resistance

Persistent moisture and limited sunlight can encourage organic growth on many Seattle roofs.

PVC roofing helps reduce these issues because its surface does not readily absorb water and is less hospitable to moss, algae, and mildew compared to more porous materials.

This resistance can translate into less frequent cleaning and fewer surface-related maintenance concerns over time.

In addition, PVC membranes are known for tolerating environmental exposure common in urban settings, helping preserve surface condition and appearance longer under typical regional conditions.

With routine inspections and basic upkeep, PVC remains one of the lower-maintenance membrane roofing options available for low-slope roofs in the Seattle area.

Flexibility in Cool Temperatures

Seattle’s climate is defined more by consistent thermal movement than by extreme heat or cold. PVC roofing materials are engineered to remain flexible in cooler temperatures, allowing the membrane to accommodate normal expansion, contraction, and minor structural movement.

This flexibility supports long-term seam stability and helps the roofing system maintain watertight performance as buildings shift subtly over time.

On larger roof spans and low-slope assemblies, this characteristic contributes to durability and system reliability under everyday weather conditions.

Many PVC systems also feature reflective surfaces that help moderate heat buildup during warmer periods, supporting overall roof system stability without introducing unnecessary complexity.

PVC Roofing Cost in Seattle

PVC roofing in Seattle typically falls within a mid-to-premium price range for flat and low-slope roofing systems. Installed costs are commonly higher than basic asphalt solutions but competitive with other single-ply membranes such as TPO or EPDM.

This pricing reflects PVC’s suitability for low-slope conditions, where prolonged moisture exposure, slow drainage, and ponding water are common—especially during Seattle’s extended wet season.

While PVC requires a higher upfront investment than entry-level roofing materials, it is engineered for applications where long-term moisture control and durability matter more than initial cost alone.

Within the general pricing range, material selection, roof design, and installation quality all influence the final figure.

Thicker membranes, upgraded insulation packages, and more detailed flashing assemblies typically increase cost but also contribute to longer service life and more stable performance over time.

For many commercial and multifamily properties, the added durability of PVC roofing can reduce repair frequency and weather-related disruptions, helping balance upfront cost against long-term ownership considerations.

Energy performance can also play a role in overall value. Many PVC systems use reflective surfaces that help manage heat buildup during warmer periods.

While Seattle’s climate limits extreme cooling demand, larger buildings and structures with higher internal heat loads may still see operational benefits over time.

Because pricing varies widely based on roof conditions and project requirements, PVC roofing costs in Seattle are best understood as a range shaped by system design rather than a fixed price per square foot.

Factors That Affect PVC Roofing Pricing

Several variables influence the final cost of a PVC roofing project in Seattle.

Roof size affects how fixed costs are distributed. Larger low-slope roofs often achieve more consistent per-square-foot pricing, while smaller roof sections may price higher due to similar mobilization and detailing requirements.

Roof slope and drainage design are also important. Flat and very low-slope roofs may require additional planning for water flow, tapered insulation, or drainage improvements, which can increase overall cost.

Roof complexity plays a major role. Penetrations such as vents, skylights, and rooftop equipment require custom flashing and additional labor. Roofs with numerous penetrations or irregular layouts generally cost more to detail correctly.

Material specifications further influence pricing. Membrane thickness, insulation type, and cover boards affect both performance and cost. Higher-spec assemblies typically offer greater durability and thermal performance but come at a higher initial price point.

Local labor conditions and contractor experience also matter. PVC roofing requires specialized installation methods, and experienced installers who follow manufacturer guidelines may charge more while reducing long-term risk on moisture-sensitive roof systems.

Additional considerations can include tear-off requirements, deck condition, code-driven upgrades, access limitations, and warranty specifications.

These factors are not unique to PVC roofing but can significantly affect the total investment on Seattle-area projects.

PVC Roofing Lifespan and Warranties

PVC roofing is widely recognized for its long service life on flat and low-slope roofs in Seattle when installed correctly and maintained at a basic level.

Its resistance to moisture, UV exposure, and common environmental stressors makes it well-suited for the region’s prolonged wet seasons and moderate temperature patterns.

Actual lifespan varies by project. Installation quality, system design, product selection, and long-term care all influence how long a PVC roof performs as intended.

As with most low-slope roofing systems, material capability alone does not determine outcomes—how the roof is detailed and supported over time matters just as much.

For property owners, PVC roofing is generally viewed as a long-term roofing investment, particularly where water exposure, ponding, and limited drying time are ongoing concerns.

Expected Service Life in Seattle Conditions

In Seattle’s moisture-heavy environment, PVC roofing systems commonly deliver decades of functional performance when properly installed and monitored.

The membrane’s non-absorptive surface helps limit common moisture-related deterioration seen in other flat roofing materials.

PVC’s ability to tolerate standing water, repeated wet cycles, and seasonal temperature movement contributes to its longevity on low-slope roofs.

Over time, this resistance can reduce the likelihood of premature surface breakdown, seam-related issues, and moisture-driven degradation.

Like all roofing systems, PVC performs best when basic care is provided. Regular professional evaluations and attention to drainage conditions support long-term reliability and help preserve the system’s intended service window.

Manufacturer vs Contractor Warranties

PVC roofing protection typically involves two separate warranty layers: manufacturer warranties and contractor workmanship warranties.

Manufacturer warranties focus on the roofing materials and system components, offering coverage for defects or premature material failure under normal conditions. Coverage length and scope depend on the specific system configuration and product specifications.

Contractor warranties address installation quality, including seam work, flashing details, and penetration sealing.

Because many flat-roof issues originate from workmanship rather than material defects, contractor experience plays a critical role in real-world performance.

Qualified PVC roofing contractors are often manufacturer-certified, which helps maintain warranty eligibility and signals adherence to recognized installation standards.

Reviewing warranty terms before installation ensures clarity around coverage duration, maintenance requirements, and claim procedures.

Selecting an experienced PVC installer familiar with Seattle’s low-slope roofing challenges reduces the likelihood of warranty disputes and improves the chances that both material and workmanship coverage perform as intended over the life of the roof.

PVC Roofing vs Other Flat Roofing Systems

PVC is one of several flat roofing systems commonly used in Seattle, alongside TPO, torch down (modified bitumen), EPDM, and older built-up roofing (BUR).

While all are designed to keep water out, they respond differently to Seattle’s defining conditions: persistent rain, long damp seasons, limited drying time, and occasional summer heat events.

PVC is a single-ply membrane system with heat-welded seams, forming a continuous waterproof surface. Other systems rely on adhesives, asphalt compounds, or layered assemblies, each with its own strengths and tradeoffs.

In Seattle’s moisture-heavy environment, performance differences tend to show up over time rather than immediately after installation.

From an energy standpoint, light-colored reflective membranes like PVC and TPO are often preferred over darker systems, which absorb more heat during warm periods.

Maintenance expectations, seam performance, and long-term durability also vary between systems, making side-by-side evaluation important for low-slope roof owners.

Rather than a one-size-fits-all solution, the “best” flat roofing system in Seattle depends on building use, roof access, drainage conditions, and long-term ownership goals.

PVC vs TPO Roofing

PVC and TPO are both white, single-ply membrane systems, and from street level, they may appear nearly identical. On the roof, however, their performance characteristics can differ based on formulation, installation quality, and long-term exposure.

PVC is known for strong seam integrity and resistance to oils, grease, and certain airborne contaminants, which can matter on buildings with rooftop exhaust, food service operations, or nearby traffic exposure.

TPO can also perform well, but durability and aging characteristics may vary more by manufacturer and product generation.

Both systems offer reflective surfaces that support energy performance, and both are widely used on commercial and residential low-slope roofs in Seattle.

For property owners comparing bids, differences often come down to expected longevity, maintenance tolerance, and confidence in long-term field performance, rather than appearance alone.

This makes PVC and TPO a common comparison point during flat roof replacement decisions in the region.

PVC vs Torch Down Roofing

PVC and torch down represent two very different approaches to low-slope roofing. Torch down systems use asphalt-based sheets applied with heat, resulting in a dense, dark surface, while PVC relies on a lighter-colored thermoplastic membrane with welded seams.

From an installation standpoint, PVC uses a flame-free process, which can be appealing on wood-framed structures or tightly spaced urban properties.

Torch down installations involve open flame and hot asphalt, which introduces additional precautions during installation and repairs.

In long-term service, torch down systems may require more frequent attention as asphalt materials age, especially in areas with standing water.

PVC’s membrane construction and seam design generally support simpler inspection and repair workflows when maintenance is needed.

Weight, heat absorption, and maintenance style are often deciding factors when comparing these two systems for Seattle-area buildings.

Is PVC Roofing Right for Your Seattle Property?

If you’re weighing PVC roofing for your Seattle property, you’re already asking the right questions.

Flat and low-slope roofs behave differently here, and choosing the right system isn’t just about materials — it’s about how your roof handles rain, drainage, access, and long-term use.

PVC roofing makes a lot of sense in many situations, but it isn’t the right answer for every building.

The best way to know is to have someone look at your roof in person, talk through what you’re seeing, and explain your options clearly — whether that ends up being PVC, another membrane system, or a repair instead of a full replacement.

If you’d like help evaluating your roof, Elite Gold Contractors can walk the surface, review drainage and details, and give you an honest recommendation based on how Seattle roofs actually perform over time. No pressure — just clear information so you can decide what works best for your property.